Getting Started with Alat Custom Diecast

Alat custom diecast is a fascinating hobby that allows you to transform ordinary diecast model cars into unique and personalized collectibles. Whether you are a car enthusiast, a model builder, or simply looking for a creative outlet, custom diecast offers a rewarding experience. This guide will provide you with the essential tips and tricks to get started, covering everything from selecting your first model to mastering advanced techniques. The journey of alat custom diecast begins with a passion for cars and a willingness to learn. With the right tools, techniques, and a bit of patience, you can create stunning custom models that reflect your personal style and creativity. This is your first step into the world of detailed miniature car modification.

Understanding Diecast Models

Before diving into alat custom diecast, it’s crucial to understand the basics of diecast models themselves. These models are typically made from a zinc alloy known as ‘diecast metal,’ which allows for intricate detailing and durability. Diecast cars come in various scales, with the most popular being 1:18, 1:24, and 1:64. Each scale offers different levels of detail and complexity, influencing the customization process. Familiarizing yourself with different diecast model types, such as classic cars, modern vehicles, and race cars, will help you choose models that match your interests and customization goals. Understanding the construction of a diecast model, including how its parts are assembled, is also key to disassembly, modification, and reassembly.

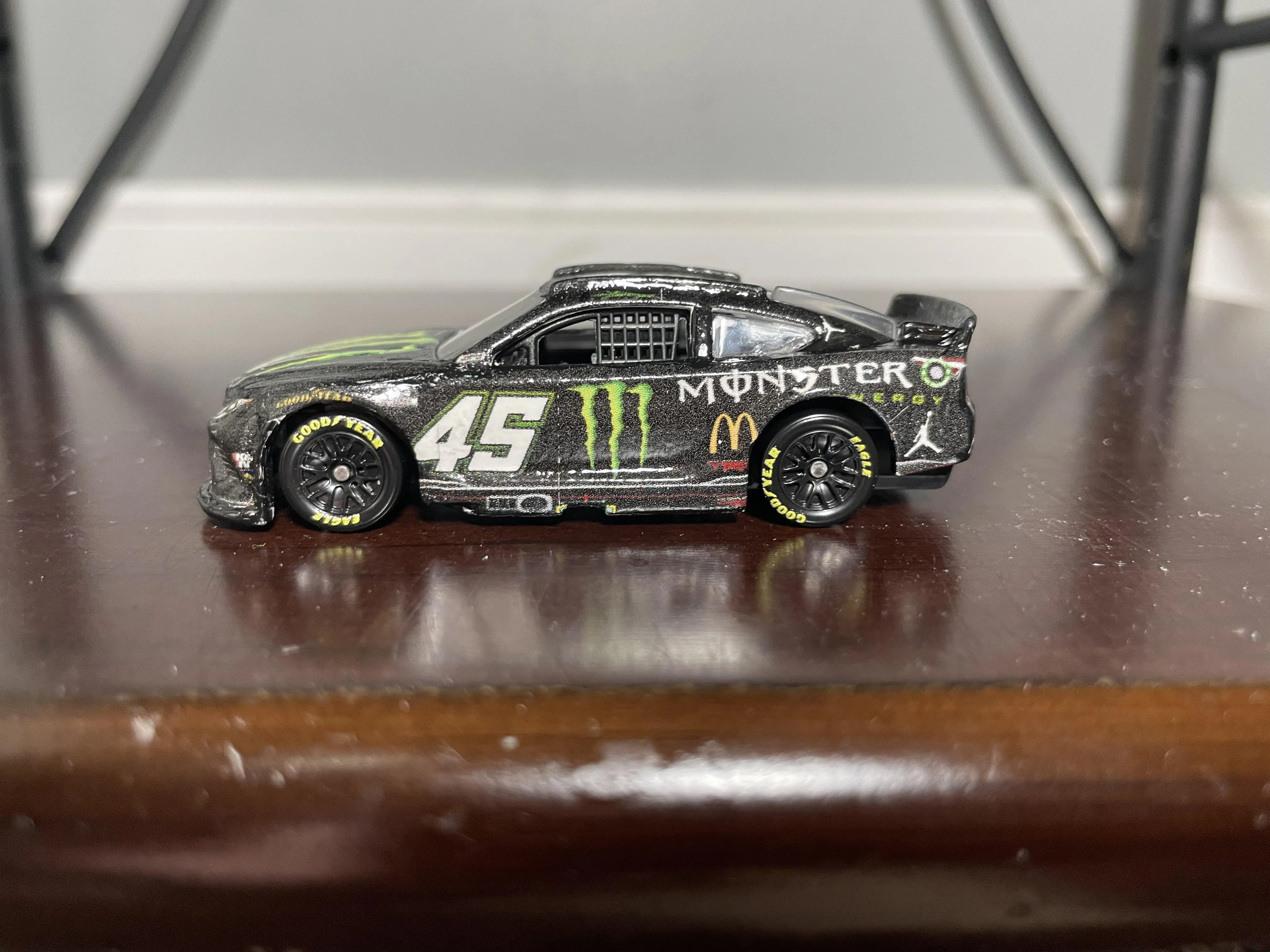

Choosing the Right Diecast Model for Customization

Selecting the right diecast model is the foundation of a successful custom project. Consider the scale, as larger scales (like 1:18) offer more space for intricate detailing, but smaller scales (like 1:64) are more cost-effective and require less space. The complexity of the model also matters; beginners may find simpler models easier to work with. Examine the model’s features, such as the presence of opening doors, hoods, and trunks, as these add to the customization possibilities. The availability of aftermarket parts, such as wheels, tires, and decals, is another factor to consider. Finally, choose a model that you are passionate about. Your enthusiasm will fuel your creativity and dedication to the project. This will help you with your alat custom diecast journey.

Essential Alat Custom Diecast Tools for Beginners

Having the right tools is critical for alat custom diecast. Start with a basic toolset, including screwdrivers (Phillips and flathead), pliers, hobby knives, and a cutting mat. These are essential for disassembling and reassembling the model. Invest in a good set of files and sandpaper with various grits for smoothing surfaces and removing imperfections. A hobby knife with replaceable blades is ideal for precise cutting. For painting, you’ll need a selection of brushes, airbrush or spray cans, and masking tape. Additionally, consider getting a small parts organizer to keep screws and small components in order. Proper lighting and ventilation are also necessary to ensure a safe and enjoyable working environment.

Basic Tools for Disassembly and Assembly

Disassembly and reassembly are fundamental steps in alat custom diecast. Begin by carefully removing screws, using the correct size screwdrivers to avoid stripping the heads. Take pictures of the model before disassembling it so you can refer back to the original configuration. Use pliers to gently remove small parts, like mirrors and wipers. Keep all screws and small parts organized to prevent loss. During reassembly, ensure that all parts fit snugly and that screws are tightened appropriately, without over-tightening them. Proper disassembly and reassembly are essential to maintaining the integrity of the model. Taking your time will pay off, and the final product will look much better, and the tool will work better too.

Cutting and Sanding Tools

Cutting and sanding are vital for preparing the model for customization. A hobby knife or modeling saw is used to cut away unwanted parts, such as spoilers or body panels. Always use a cutting mat to protect your work surface. Sanding removes imperfections, smooths surfaces, and prepares them for painting. Start with coarser grits and gradually move to finer grits for a smooth finish. Consider using sanding sticks or sanding sponges for hard-to-reach areas. Pay attention to details and try to maintain the original shape and dimensions of the model during the sanding process. This will help the final appearance and result of your alat custom diecast.

Painting and Finishing Tools

Painting and finishing bring your custom diecast to life. An airbrush is the preferred tool for a professional finish, but spray cans can also be used effectively. Choose high-quality paints designed for models, and prime the surface before painting. Apply thin, even coats, allowing each coat to dry thoroughly before applying the next. Masking tape is crucial for creating different color schemes or detailing. Once the paint is dry, apply a clear coat to protect the finish. Polishing and detailing waxes can be used to enhance the shine and protect the paint. Proper painting and finishing are what make your alat custom diecast a masterpiece.

Advanced Techniques for Alat Custom Diecast

Preparing the Diecast Surface

Surface preparation is key to a successful paint job. Start by thoroughly cleaning the diecast model to remove any dirt, grease, or old paint. Use a mild degreaser or soapy water. If the model has existing paint, gently sand it down to create a good surface for the new paint to adhere to. Fill any imperfections, such as scratches or gaps, with model filler and sand them smooth. Applying a primer is essential to provide a uniform base for the paint and enhance adhesion. Ensure the surface is completely dry and dust-free before painting. A well-prepared surface guarantees a professional-looking final result for your alat custom diecast.

Painting Techniques for a Professional Finish

Achieving a professional finish requires mastering several painting techniques. When using an airbrush, control the air pressure and paint flow to achieve smooth, even coats. Practice on a test piece before painting the model. For spray cans, use short, controlled bursts and maintain the correct distance. Avoid applying thick coats, which can lead to runs and drips. Apply multiple thin coats, allowing each one to dry completely before adding the next. Use masking tape to create sharp lines and precise color separations. Consider adding a clear coat to protect the paint and give it a glossy finish. This will help improve the finish for your alat custom diecast.

Detailing and Customizing Your Diecast Model

Adding Decals and Graphics

Decals and graphics add personality and realism to your custom diecast models. Select high-quality decals that suit your design. Before applying the decals, ensure the surface is clean and smooth. Use decal setting solution to help the decals conform to the model’s curves and contours. Apply the decals carefully, avoiding bubbles and wrinkles. Once the decals are dry, apply a clear coat to seal them and protect them from damage. Experiment with different decal types and designs to achieve the desired look. Decals can significantly enhance the overall look of your alat custom diecast.

Weathering and Aging Effects

Weathering and aging effects add realism to your model, giving it a used or vintage look. Use weathering powders, washes, and dry brushing techniques to simulate dirt, rust, and wear. Apply washes to panel lines and recesses to enhance details. Dry brushing involves lightly applying paint to raised surfaces to create a worn effect. Experiment with different techniques to achieve the desired level of weathering. Practice on a test piece before applying weathering effects to the model. Weathering is an effective way to give your alat custom diecast a more realistic feel.

Tips for Safety and Best Practices

Safety Precautions

Safety should always be a top priority when working with alat custom diecast. Wear appropriate personal protective equipment (PPE), such as safety glasses, a dust mask, and gloves. Work in a well-ventilated area, especially when using paints, solvents, and adhesives. Avoid inhaling fumes and vapors. Properly dispose of used materials, such as paint and solvents, according to local regulations. Always supervise children when working with tools and materials. Read and follow the manufacturer’s instructions for all tools and materials. Following these safety precautions is essential for a safe and enjoyable alat custom diecast experience.

Maintaining Your Alat Custom Diecast Tools

Maintaining your tools is crucial for their longevity and optimal performance. Clean your tools after each use, removing any paint, glue, or debris. Store your tools in a dry, organized location. Sharpen blades regularly and replace them when they become dull. Lubricate moving parts, such as hinges and joints. Clean airbrushes and spray guns thoroughly after each use. Proper tool maintenance ensures that your alat custom diecast tools remain in good condition and ready for your next project. This also helps to extend the life of your tools, and saves you money on buying replacements.